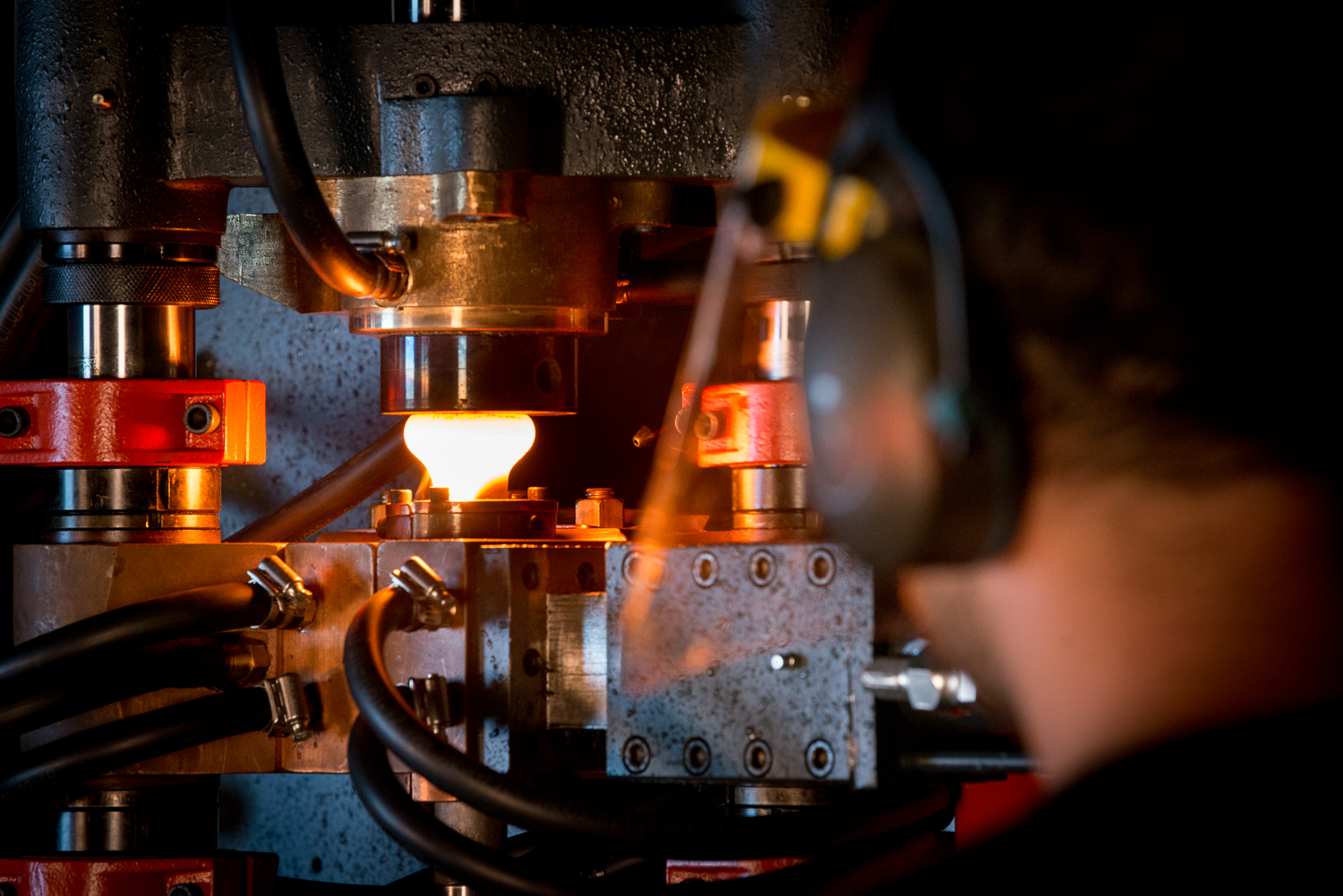

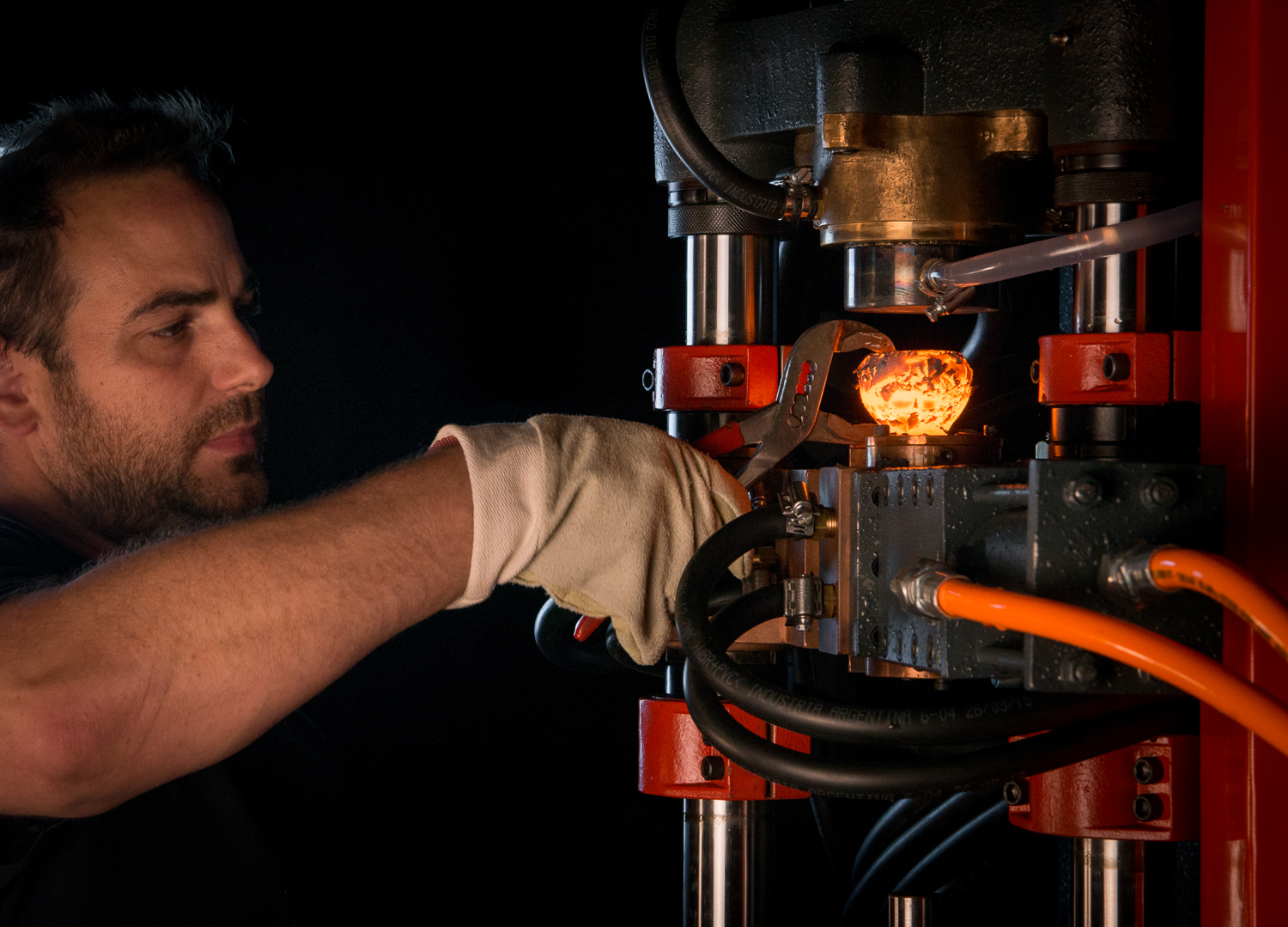

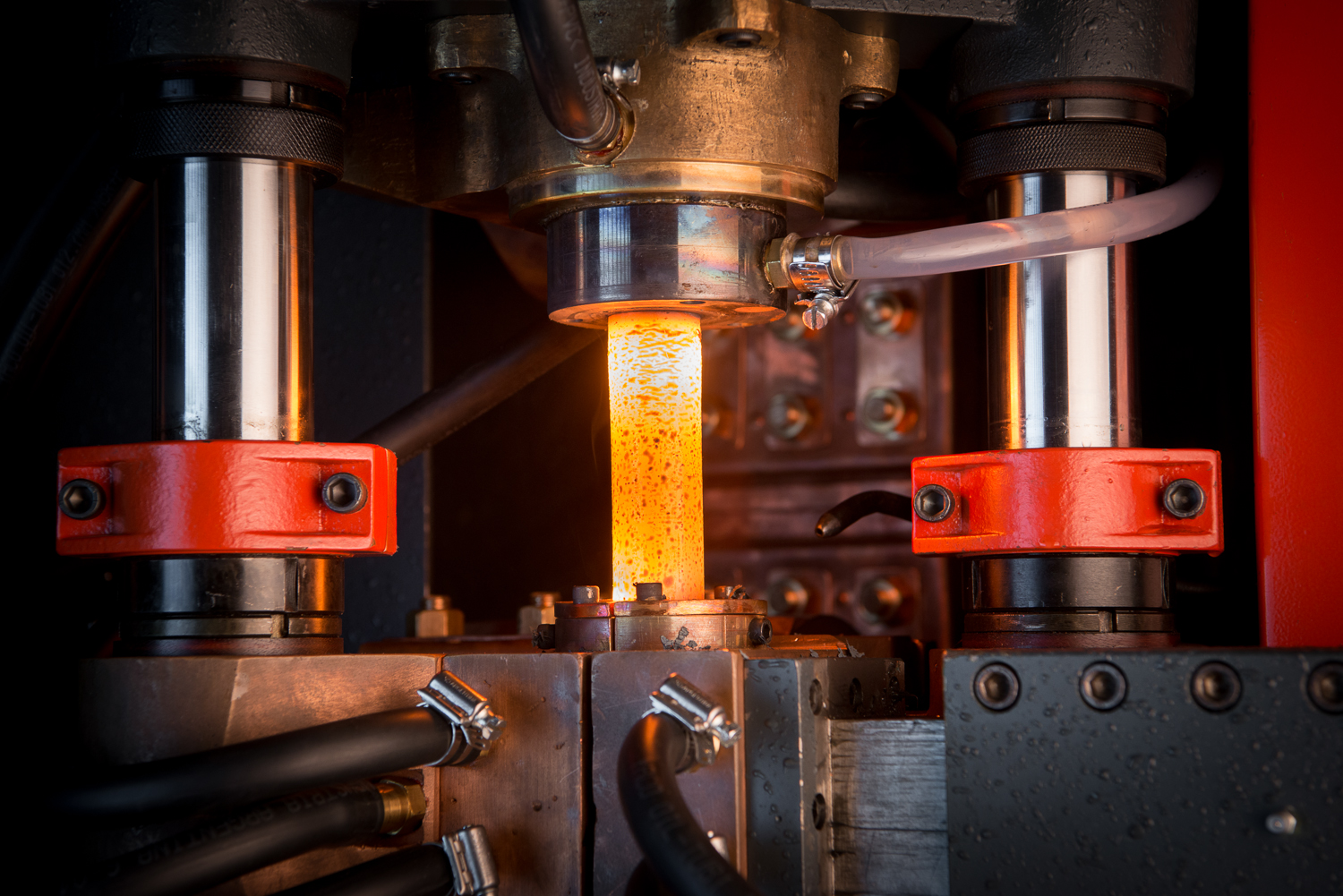

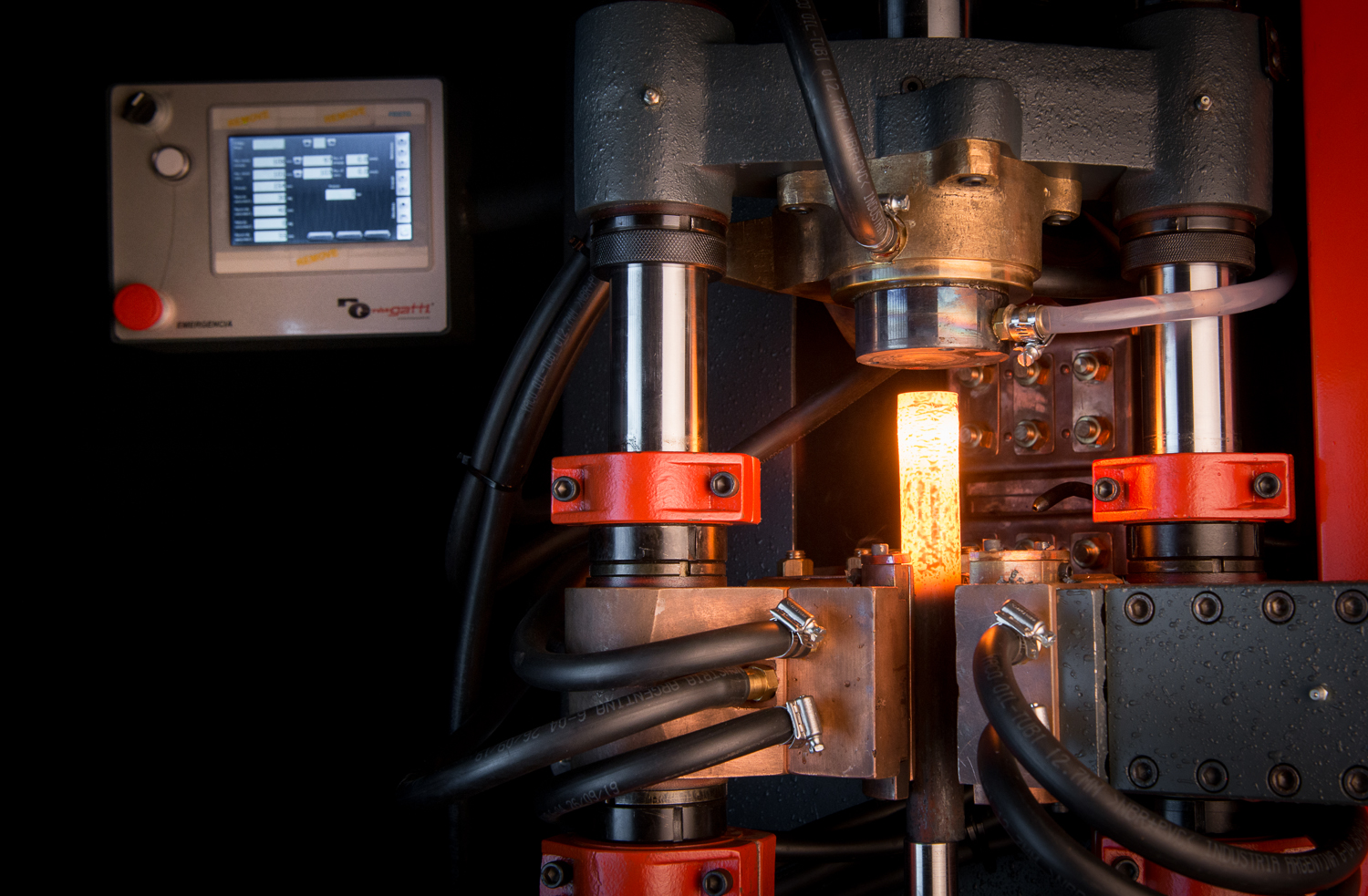

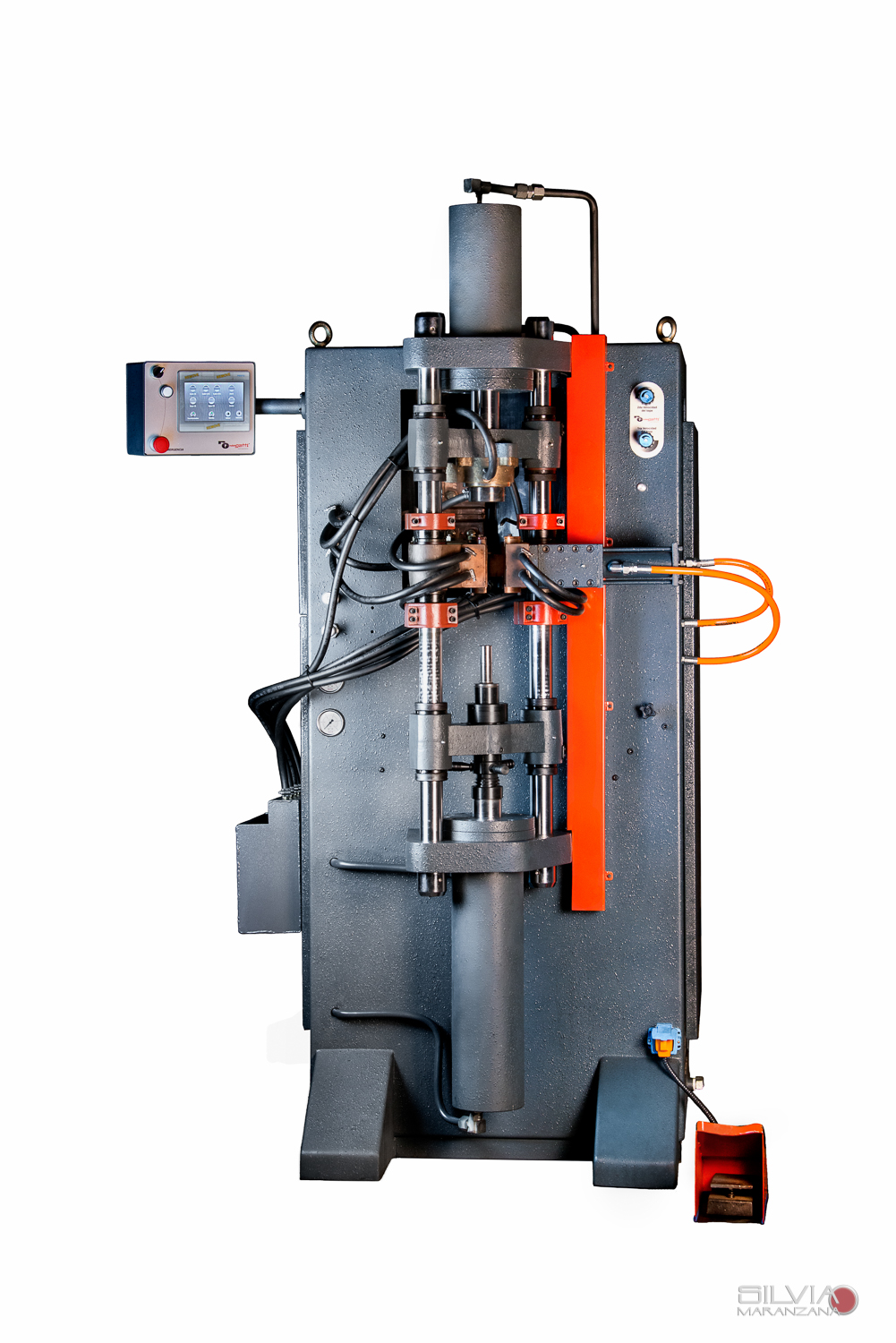

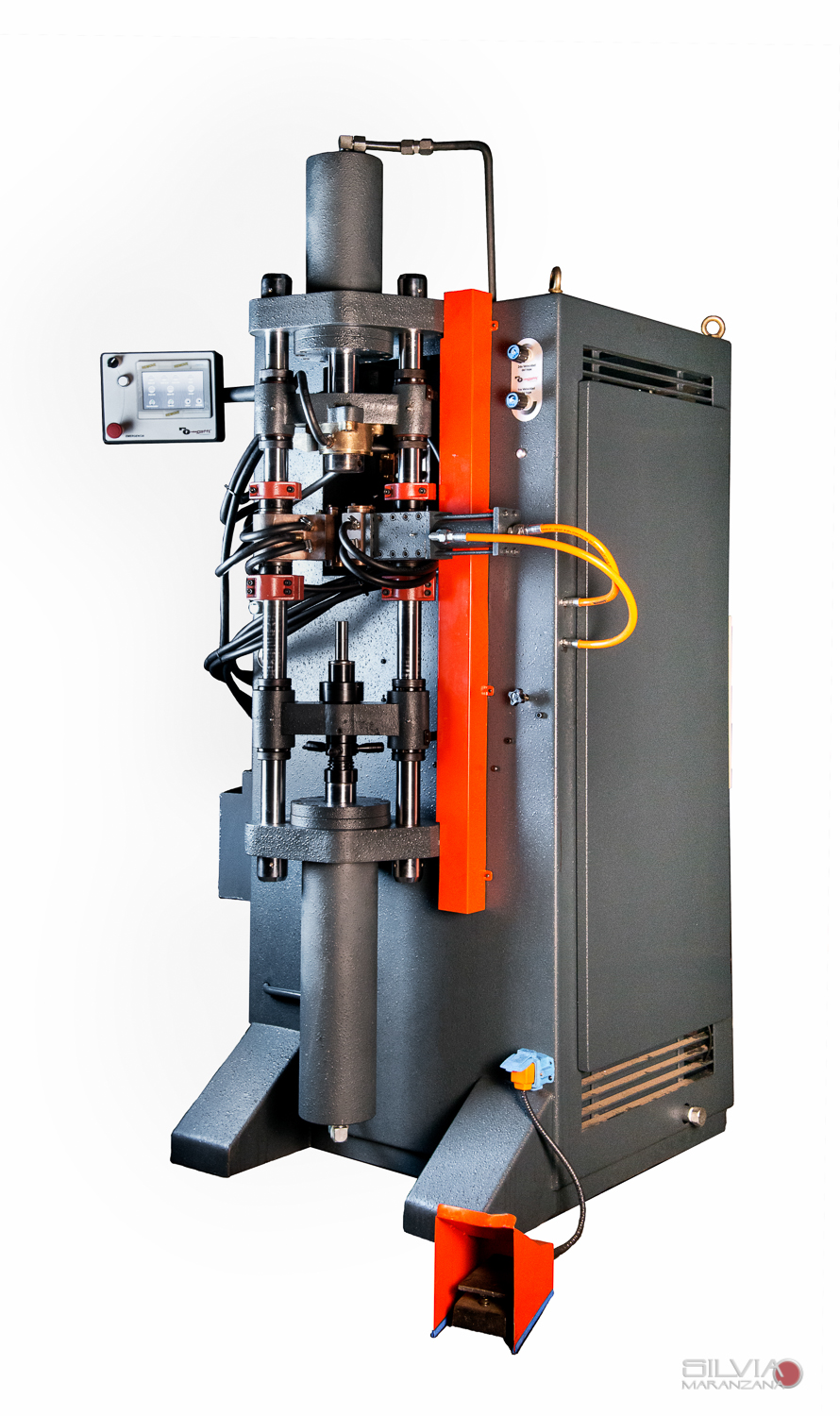

Vertical Hydraulic Electroforge Machine

Generalidades

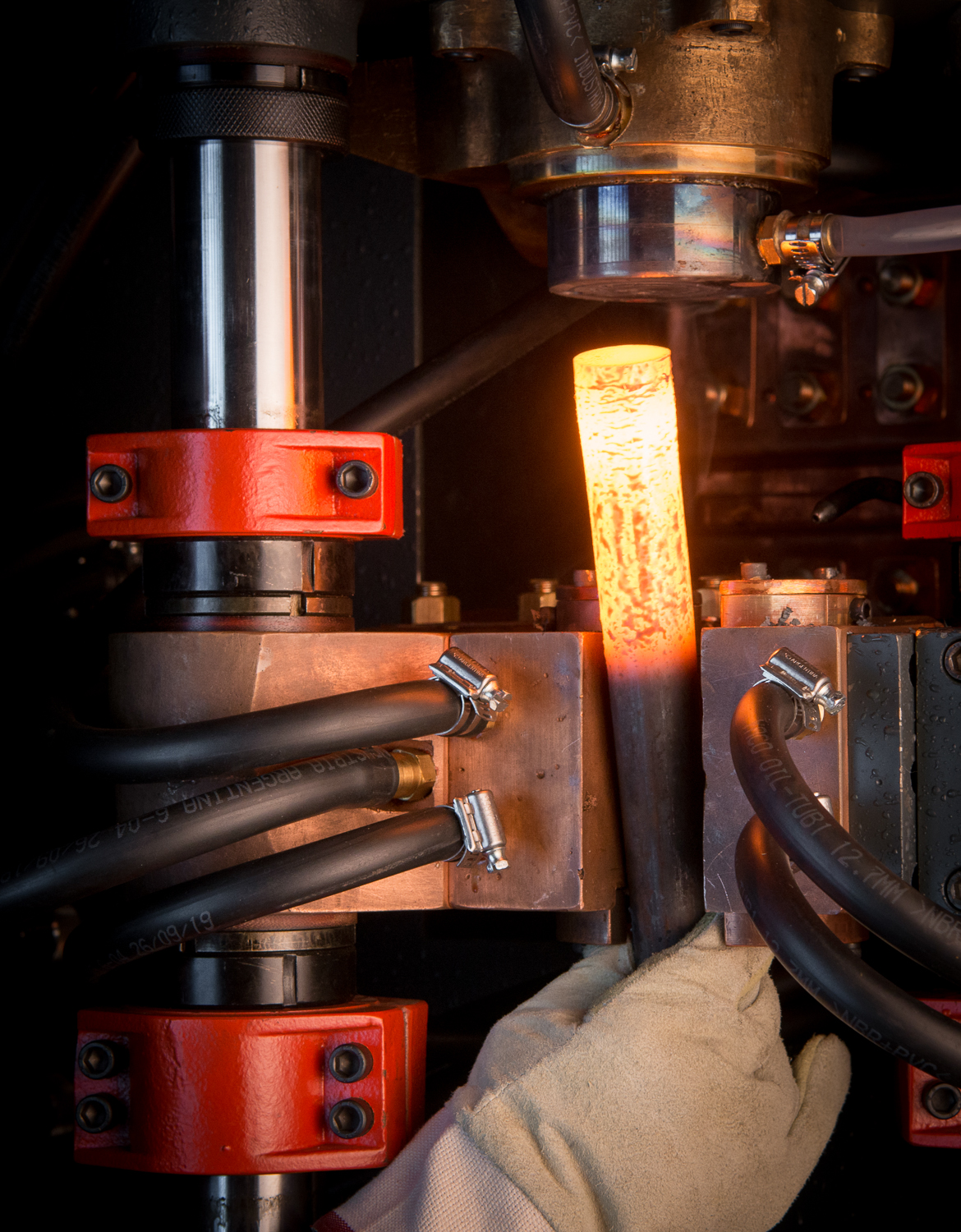

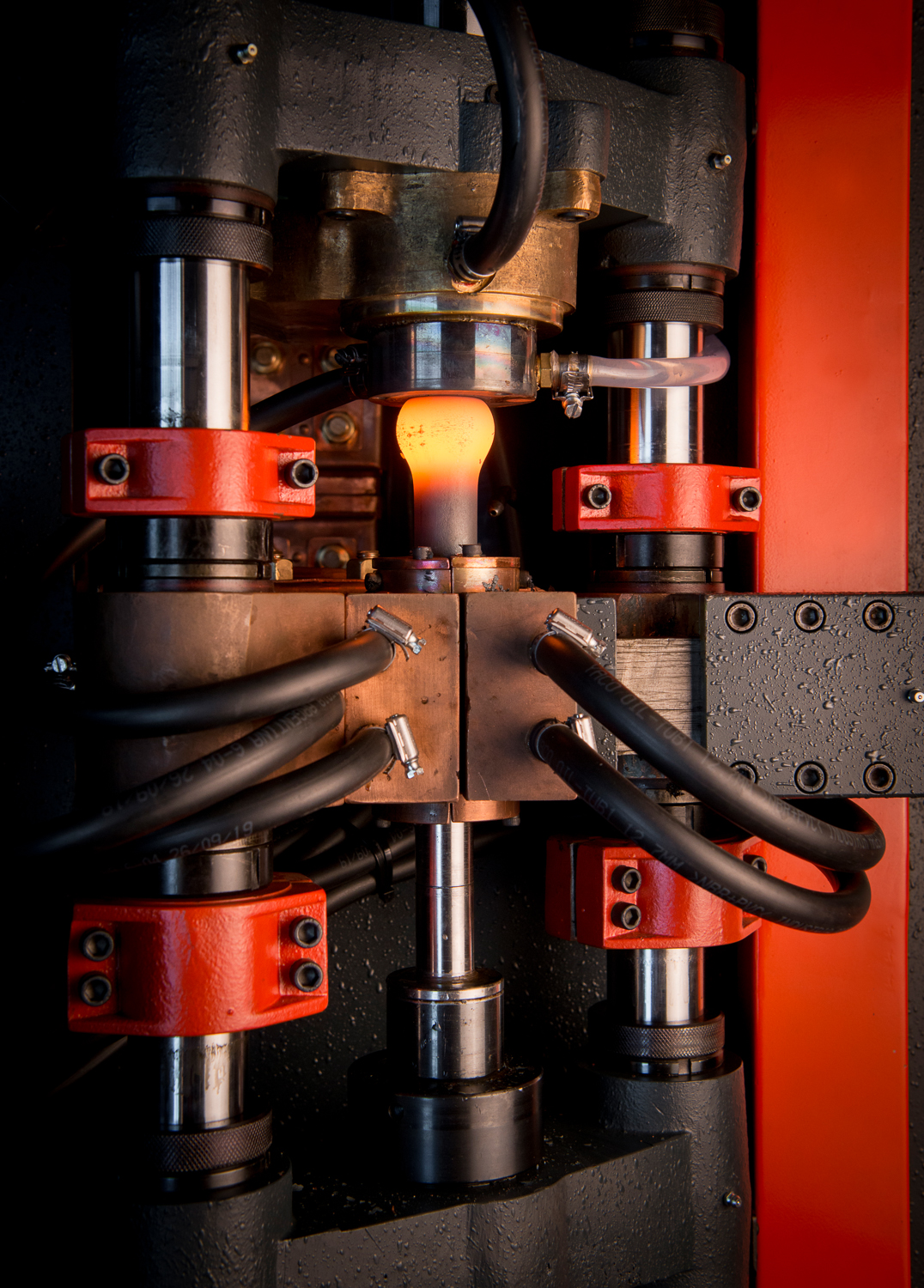

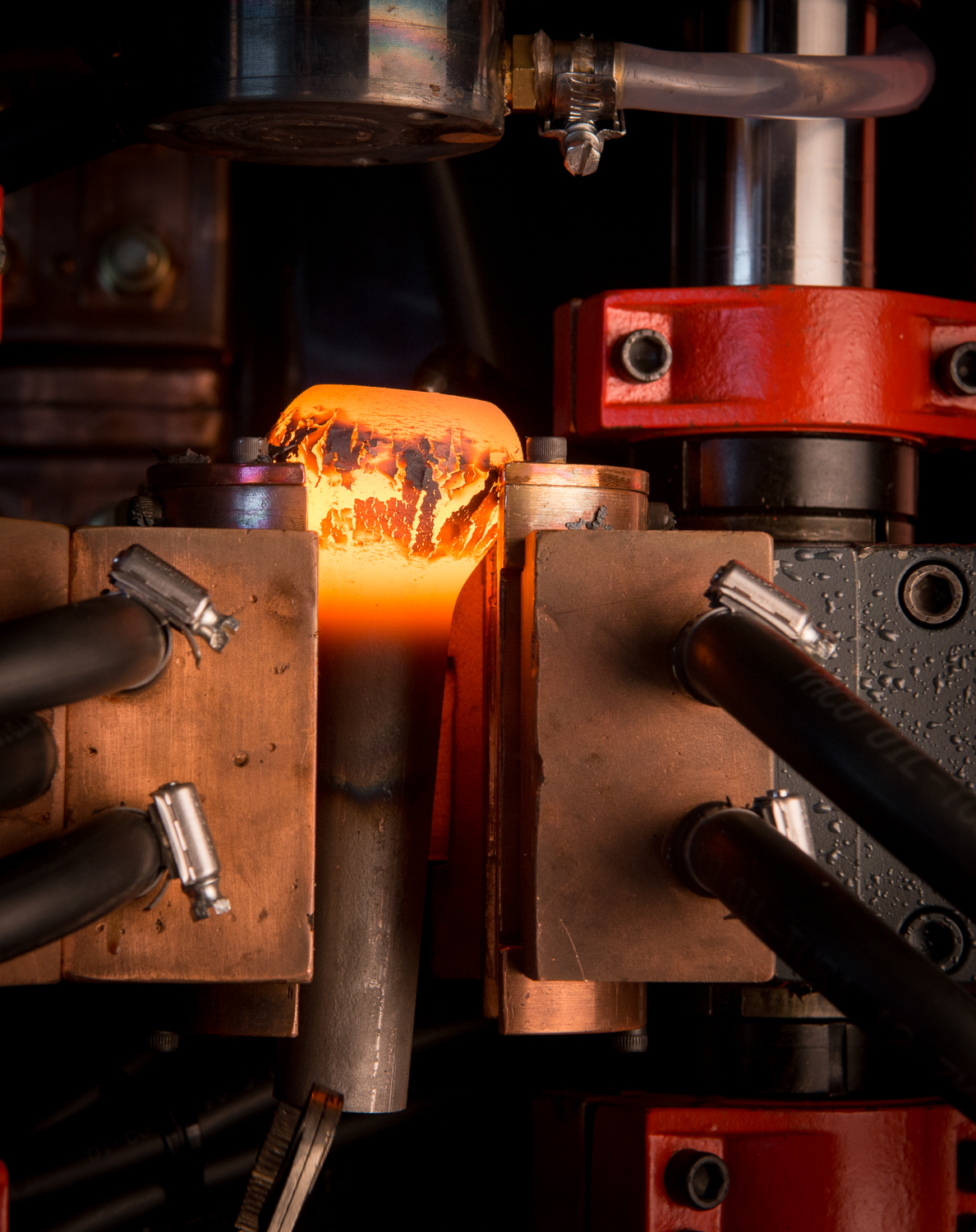

Designd to forge pieces at the end or in middle of a bar, as well as in a cylindric matrix, to produce a better piece finishing.

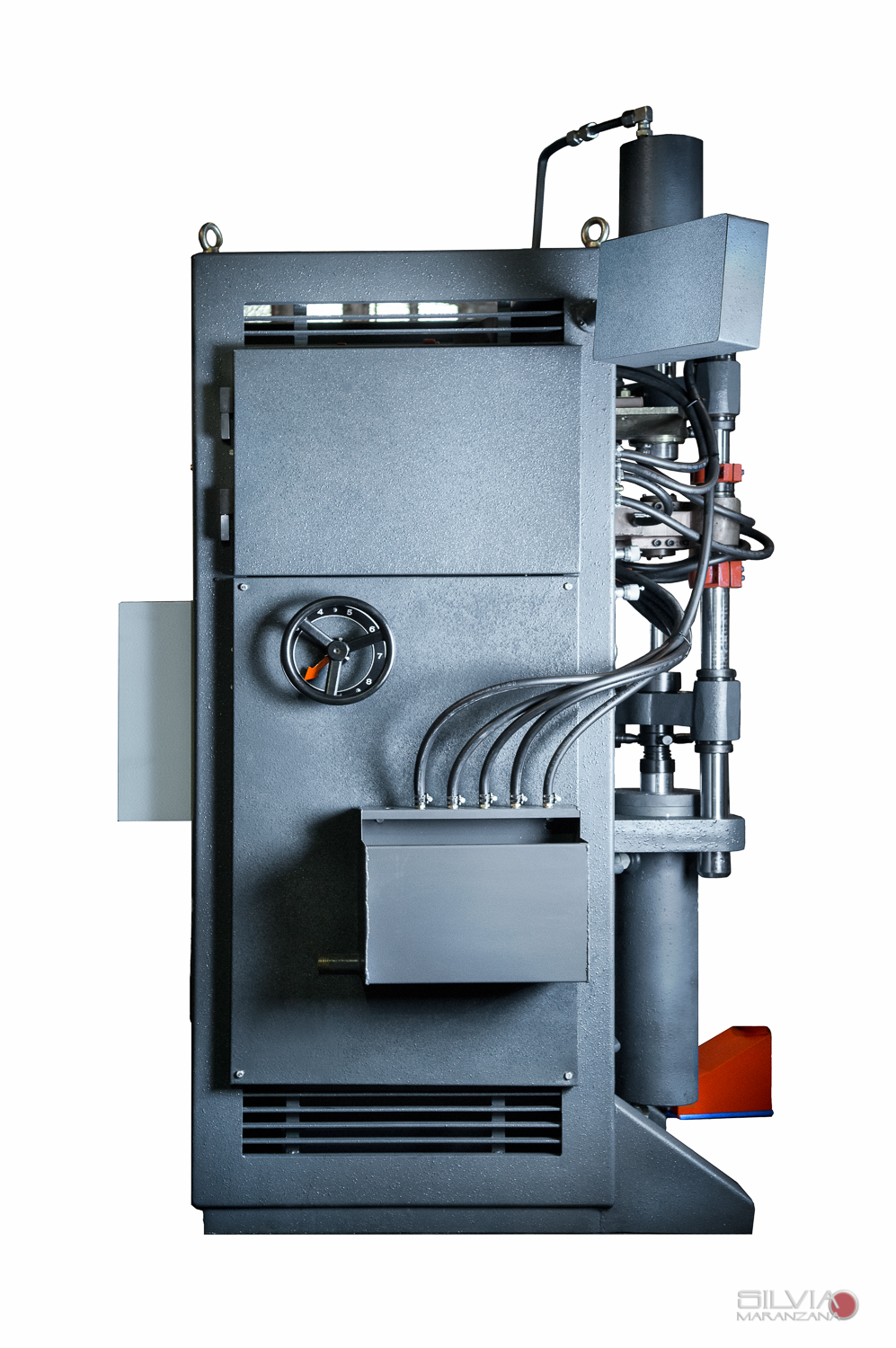

These machines can be built for one end, two end, horizontal or vertical passing bars, according to the bar's lenght.

It's powered by a rotary tandem pump, in order to achieve total independence between clamp and push circuits, so each pressure can be controlled individually.

All the machines have been provided of controlled speed escape cylinders. This makes possible to produce large volumes of forged pieces without losing the required shape.

Designd to forge pieces at the end or in middle of a bar, as well as in a cylindric matrix, to produce a better piece finishing.

These machines can be built for one end, two end, horizontal or vertical passing bars, according to the bar's lenght.

It's powered by a rotary tandem pump, in order to achieve total independence between clamp and push circuits, so each pressure can be controlled individually.

All the machines have been provided of controlled speed escape cylinders. This makes possible to produce large volumes of forged pieces without losing the required shape.

Transformer

Designed with the most advanced technique, it has attained the higher performance. Refrigeration: circulating water and forced ventilation. Heating capacity: 2-3 Kg/KWh. Power consumption: 0,35 - 0,50 KWh / Kg heated material.

Tecnical details

| MODEL | RGH 40 | RGH 70 | RGH 100 | RGH 200 |

| Transformer power KVA | 40 | 70 | 100 | 200 |

| Bar to forge Ømm | 10 a 28 | 12 a 35 | 13 a 45 | 14 a 60 |

| Max forging bar lenght, Standard mm | 1050 | 1300 | 1500 | 2000 |

| Max forging bar lenght, Passing bar | NO LIMIT | |||

| Max Heating capacityKg/h | 50 a 65 | 80 a 110 | 120 a 160 | 220 a 300 |

| Limit Dimensions Lenght x Height mm | 2500 x 1580 | 2770 x 1580 | 3200 x 1650 | 400 x 1650 |

| Depth mm | 950 | 1100 | 1700 | 2500 |

| Transformer regulator | 8 low positions and 8 high positions | |||